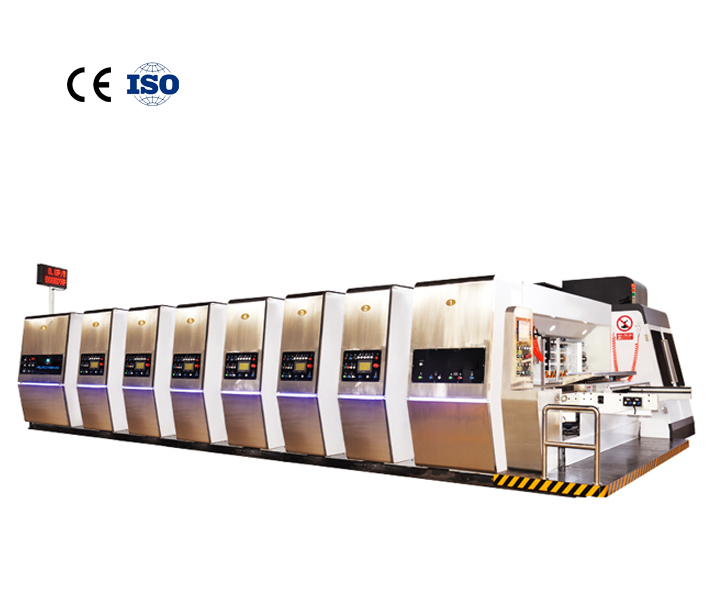

Hcl-1244 high speed ink printing die-cutting machine

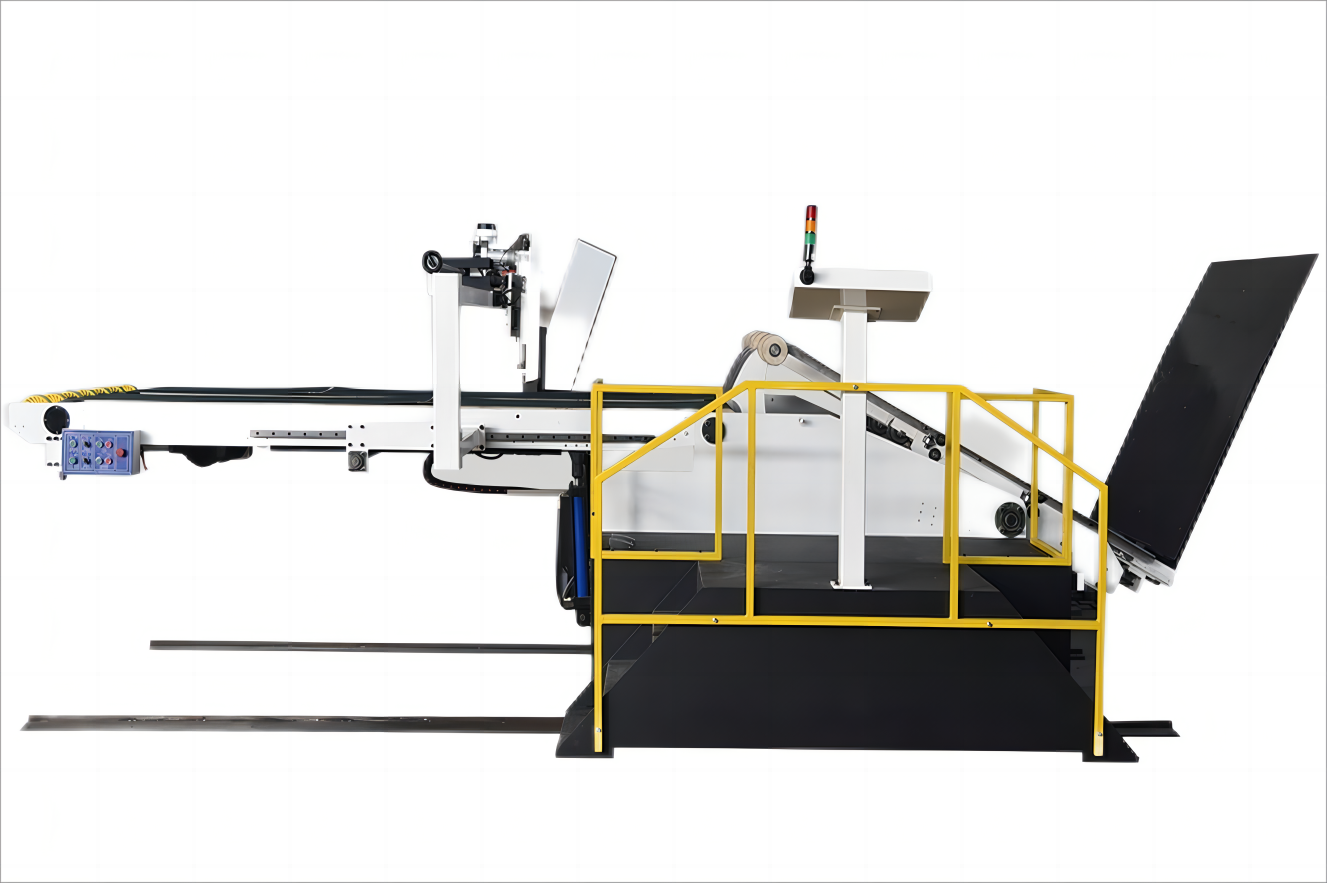

Paper feeder function

(1)Shandong Komori wheeled paper feeding structure, high speed, smooth and accurate paper feeding

(2) High-strength air suction fan, air suction auxiliary paper feeding, wind suction force can be manually adjusted, the fan is 7.5KW, or according to the different bending conditions of the cardboard, the air volume can be adjusted, the general bending uneven cardboard smoothly through, to ensure smooth paper supply.

(3) Alternate sheet feeding device. (Continuous and spaced feeding is optional)

(4) The positioning datum of feeding mechanism is scientific and reasonable, with high precision.

(5) Supply paper electronic counter, set and display the production quantity.

(6) The front plate lifting turbine box adjustment, instrument handle display scale, accurate position, convenient adjustment.

witch is set for each color group

■ The mesh cap feeding section works with the lifting, and the gap between the printing plate is electrically adjusted when inking; Printing plate with the paper suction bellows pressure frequency control, the well can be adjusted separately the air volume setting.

■ Adopts new technology to ensure field printing and compatible with high dot printing above 60 lines.

■ Optional sealing cavity double scraper uniform inking mechanism, using the whole 19 type uniform inking anti-seepage device, to avoid ink spilt during work; The special Angle of the blade is evenly twisted to transfer ink, which can easily realize 100-line dot printing, and prolong the service life of the blade and the reticulated paper

■ The printing phase is attached with electromagnetic hybrid machine, which can automatically lock the tooth gun position when the machine is separated to prevent the plate ring zero position loss.

The printing plate is equipped with 勧 foot switch, which can be quickly hung, adjusted, convenient for plate change and scrub.

Die cutting function

(1) the diameter of 530 mm (including edition) Ø. High quality steel (2) The surface of the steel tube is ground and hard branded. (3) Balance correction,stable operation.

Die-cutting roller(upper) (1) 530mm, surface grinding, hard burning plating, smooth movement. (2) Speed limit compensation device is installed. (3) The rubber cushion roller moves 40mm horizontally to extend the service life of the rubber cushion. (4) Automatic repair device can improve the utilization rate of rubber mat for 3-4 times.

| odel | 1250mm |

1450mm |

1650mm |

| The machine width | 2000/2600/2800/3000mm

|

2000/2600/2800/3000mm

|

2000/2600/2800/3200mm

|

| Design speed | 180piece/min |

150piece/min |

140piece/min |

| Economic speed | 150piece/min |

120piece/min |

120piece/min |

| Maximum feed size | 1700/2300/2600/2700mm |

1700/2300/2600/2700mm |

1700/2300/2500/2900mm

|

|

Minimum feed size |

300×500mm

|

350×500mm |

500×650mm |

|

paper thickness |

0-12mm |

||

|

Tinted precision |

three color±0.5mm |

||

|

Maximum printing area |

1600/2200/2500/2600mm | 1600/2200/2400/2600mm | 1600/2200/2400/2800mm |

|

The standard version of thickness |

7.2mm |

||

|

Axial adjustment of printing roller |

±15mm |

||